Your Advantages

Faster Development

Reduce pre-development and series-development time to 25 months until SOP.

Process Cost Savings

Streamline material and PPAP approval for parts, components, and assemblies across the supply chain and OEMs.

Increased Efficiency

Boost efficiency for suppliers and OEMs by up to 45% in the initial phase.

Shortened

Development

Reduce production and development time to 25 months until SOP.

Simplified

Approval

Streamline material and PPAP approval for parts, components, and assemblies across the supply chain and OEMs.

Increased

Efficiency

Boost efficiency for suppliers and OEMs by up to 45% in the initial phase.

Simplify Your Work Now

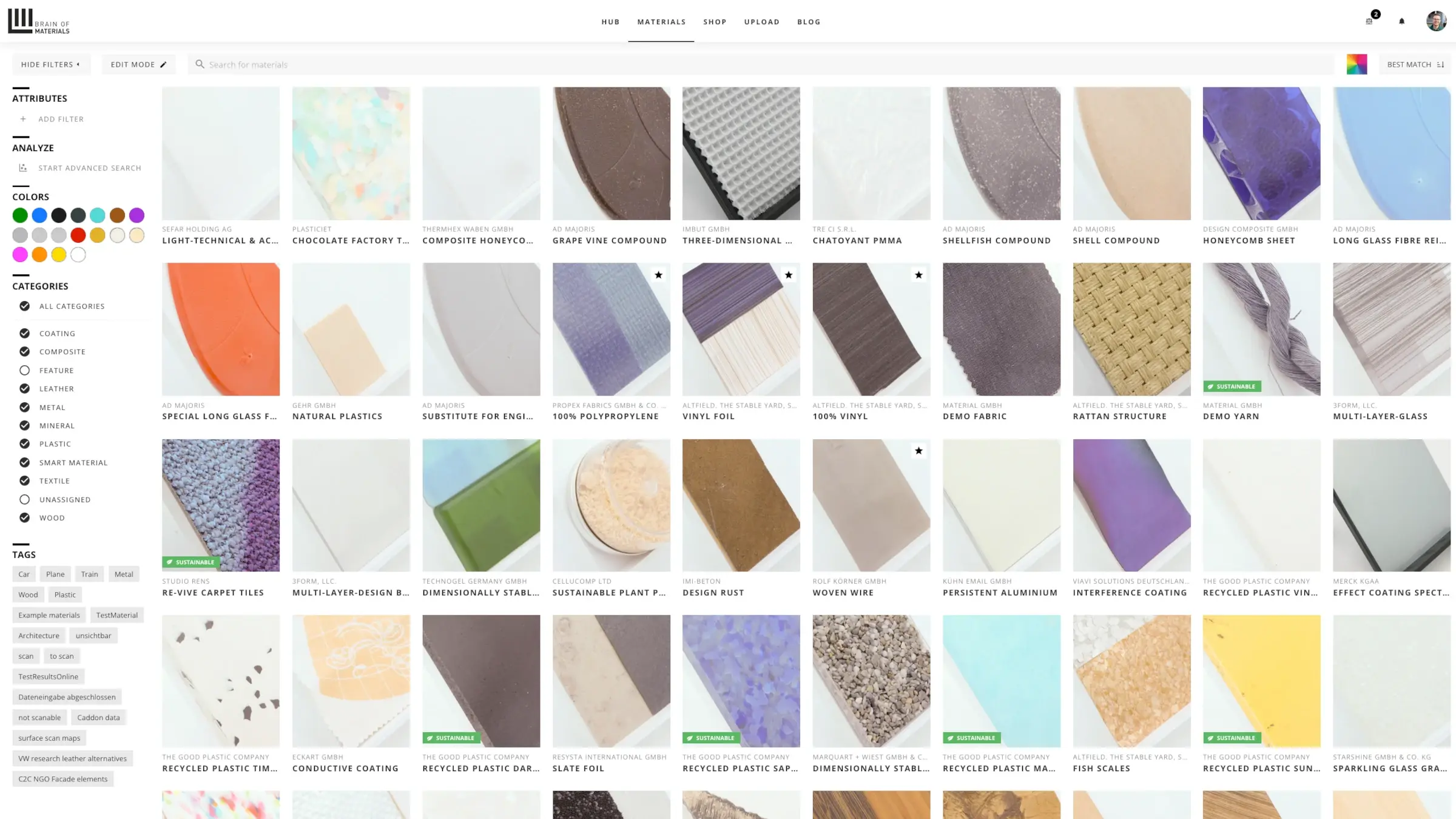

How it works

Streamlined Processes for Suppliers and OEMs

Digital Specifications

Brain of Materials provides suppliers and OEMs with digital, machine-readable delivery specifications and requirements, including test standards.

Instant Compliance Checks

Quickly showcase where parts and materials meet the requirements of OEMs and Tier-1 suppliers including technical data sheets and test reports.

Intelligent Recommendations

Brain of Materials simplifies searches and generates recommendations based on technical drawings, material properties, and experiential data.

Services & Solutions

Automated Delivery Specifications

Digital and machine-readable delivery specifications and requirements, including test standards. Quick validation of purchased parts and materials against OEM and Tier 1 requirements.

Optimized Sample and Part Testing

Targeted, cost-efficient, and resource-saving planning and organization of test samples and parts. Accurate and automated reporting for seamless customer communication.

Inspection Plans for Testing & Validation

Automatic provision of necessary inspection plans for initial warranty confirmation and PPAP. Seamless connection with recommended test service providers or internal labs.

Library Function

Facilitates the search for suitable information based on technical component drawings and material properties.

- No unauthorized exchange of material and product data.

- ISO 9001 and TISAX certified processes.

- Regular penetration tests to prevent security gaps.

Your data security is our priority, ensuring trust and reliability in every step of the process.

Already partnering with us

You’re looking for answers how to increase your efficiency by 45%?